Process Safety Culture

Process Safety Culture, as defined by the Center for Chemical Process Safety (CCPS) sub-committee on culture in Essential Practices for Developing, Strengthening, and Implementing Process Safety Culture, published in 2016, is:

The pattern of shared written and unwritten attitudes and behavioral norms that positively influence how a facility or company collectively supports the development of and successful execution of the management systems that comprise its process safety management program, resulting in the prevention of process safety incidents.

Improving PSM culture is crucial for enhancing overall process safety management (PSM) performance. It starts with senior management’s commitment to understanding and enhancing the culture, recognizing its drivers and manifestations. Ultimately, senior management bears the primary responsibility for fostering a robust culture, as their actions set the tone and direction for the entire organization’s commitment to safety.

The CCPS Risk-Based Process Safety (RBPS) Guidelines emphasize commitment to process safety, understanding and managing risks, and learning from experience. To achieve this, facilities must develop a culture that prioritizes process safety, complies with regulations, enhances organizational competence, and engages stakeholders. Recognizing this need, CCPS initiated a guideline project, culminating in the publication of the aformentioned book Essential Practices for Developing, Strengthening, and Implementing Process Safety Culture, published in 2016, and AcuTech was proud to serve as the lead author.

By fostering a positive safety culture, organizations can reduce the likelihood of incidents and catastrophic accidents, thereby minimizing risks and promoting trust. A strong safety culture not only enhances organizational effectiveness and reputation but also facilitates proactive hazard identification and mitigation, ultimately promoting responsible operations. Collaborative efforts, committed leadership, and guidance on implementation are vital. While PSM implementation has traditionally focused on technical and managerial aspects, the industry lacks a defined process for addressing underlying PSM culture.

Assessing and Enhancing Process Safety Culture with the AcuTech Protocol

AcuTech culture analyses examine operations with respect to key principles as defined the safety culture book. AcuTech’s safety culture assessment protocol includes questions on each of the 10 key elements of process safety culture:

- Establish an Imperative for Safety

- Provide Strong Leadership

- Maintain a Sense of Vulnerability

- Understand/Act Upon Hazards/Risks

- Empower Individuals to Fulfill their Safety Responsibilities

- Defer to Expertise

- Ensure Open and Frank Communications

- Foster Mutual Trust

- Combat Normalization of Deviation

- Learn to Assess and Advance the Culture

Responses to these questions are analyzed to provide a complete picture of the process safety culture at each facility of interest.

Effective efforts to improve safety must be based upon:

- An understanding of the hazards and risks of the facilities and their operations.

- An understanding of the demand for, and resources used in, process safety activities.

- An understanding of how process safety activities are influenced by the culture within the organization.

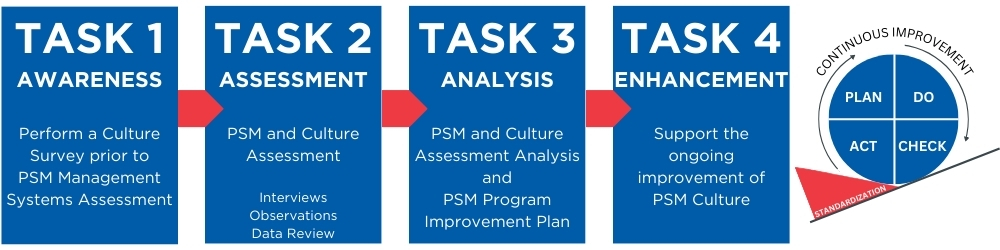

- Process Safety Culture Surveys

- PSM & Culture Assessments

- PSM Program Improvement Plans

- Enhancement of PSM Culture

AcuTech consultants have contributed to the following standards, codes, and programs.

- AcuTech is the author of Essential Practices for Creating, Strengthening & Sustaining Process Safety Culture, 2nd. Ed. (2016) and has conducted process safety culture audits at facilities using our internal culture protocol.

- Experience in leading safety culture transformation and process safety program implementation – AcuTech’s projects have included audits and safety culture assessments for of a wide variety of facilities (including refineries), including; the development of standard operating procedures, preventative maintenance programs, operator training programs, incident investigation programs and emergency response plans; process hazard analyses, safety instrumented systems reviews, human factors studies, facility siting studies and risk assessments.

- Proven track record and experience in the field of safety performance improvement and culture transformation. AcuTech is globally recognized for its expertise in process safety management, with specialization in the oil/gas and chemical process industries. AcuTech has extensive experience in assisting with development and implementation of process safety management programs, including programs that are not specifically required by regulation.